About the project

Agro2Circular addresses challenges in the agrifood sector, including:

The vast amounts of food waste/residues being produced.

Inefficient extraction methods for bioactive compounds from fruits and vegetables (F&V).

Multilayer plastic films used for packaging and crop protection which lack recycling solutions.

Relatively low use of digital technologies compared to other industries.

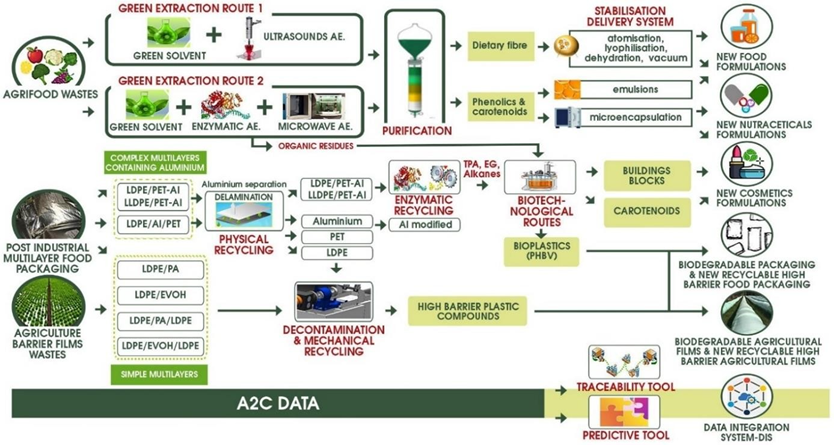

Agro2Circular proposes a territorial systemic solution, powered by digital tools, to upcycle F&V residues and multilayers into high-value products. The project involves key actors Spain, Italy and Lithuania.

The Agro2Circular project will address this challenge by developing a Data Integration System (DIS) platform. The DIS will include a Traceability Tool to identify materials and their processes, as well as a Decision Support Tool to predict material characteristics and explore alternatives for valorisation. By processing data and facilitating circular supply chains, DIS will accelerate the transition to a circular economy in the agrifood sector.

Description of success

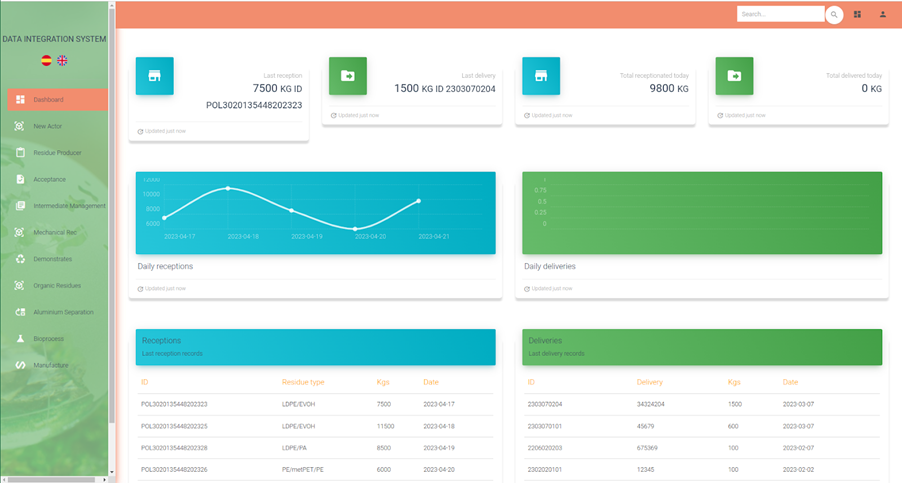

The project has developed the beta version of its software tool, the DIS platform, which allows real-time collection and transfer of agri-food plastic waste data for traceability purposes.

The tool uses various information and computing technology (ICT) tools to create a cloud-based platform capable of incorporating information from any internet-connected device.

The project milestones included:

analysis of the supply chain for multilayer plastic waste and agri-food by-products

defining and development of traceability methodologies

multi-criteria decision-making

system architecture design, development and testing

tool integration

Highlights

Agro2Circular‘s DIS platform includes:

A combination of essential tools: the inclusion of a traceability tool (to identify materials and their processes) linked to a multi-criteria predictive/decision tool (to predict material characteristics and explore alternatives to enhance their value).

Easy access: using different different ICT tools, the solution provides a cloud-based platform capable of collecting information from any internet-connected device.

High security: incorporating blockchain technology ensures that all information is guaranteed and secure.

Outputs

The beta version of DIS has been produced, incorporating the following:

Plastic data flow has been tested by all stakeholders treating the residues.

Organic waste flow architecture has been included for traceability.

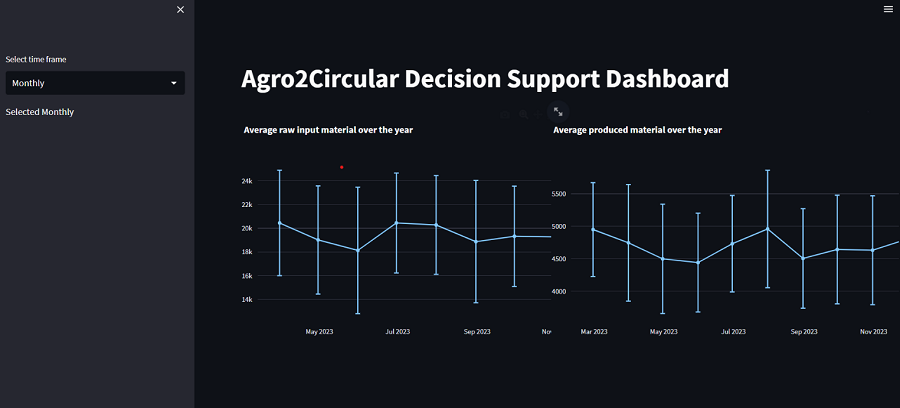

Plastic value chain statistics are provided, together with expected results.

Impact

DIS represents a significant advancement in data management and distribution for traceability and waste recovery options in the agri-food sector.

It offers a comprehensive agri-food and multi-layer plastics waste database, a real-time traceability tool integrated with various ICT tools, and a predictive/decision tool powered by big data and artificial intelligence. The traceability tool ensures compliance with European standards and uses blockchain technology for secure and immutable data. The predictive tool analyses and simulates data to make strategic decisions and select the best recovery routes based on various criteria.

Lessons

The main challenges overcame were:

the large number of stakeholders in the value chain that need to be connected (waste producers, waste managers, recyclers/upcyclers, end-users;

the lack of digitalisation in the sector; and

the incoming new processes which gather the residues and products treatment that in many cases are at lab/semi-industrial scale and which lack of definitive data .

Other information

(click the images to view larger versions)

Figure 1: Value chains covered by Agro2Circular

Figure 2 &3: Screenshots of the beta version of the DIS